Crystal River Optics was established in 1994 by Ted Judd, Optical Manufacturing Specialist with over 40 years experience. The company was started and remains today as a sole proprietorship. The owner believes that he can provide the best service to his customers when he handles all the optical issues himself, particularly when dealing with prototypes. He is a master optician having been trained at Perkin Elmer by German craftsmen in the old European tradition. His expertise includes hand polishing of all types of delicate crystals.

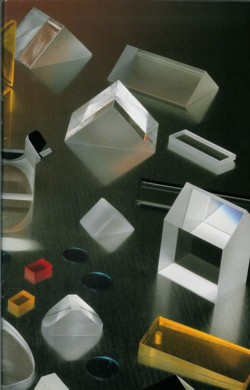

Crystal River Optics will be responsible for purchasing the raw materials, fabrication, thin film coating, assembly of complex optical systems and provides complete quality inspection certificates. Custom rework of your damaged components or assemblies can also be provided. Although a sole proprietor, the owner does use trusted quality vendors and part time technicians to meet the customers optical requirements. Consulting is also available to help solve your optical issues.

Ted Judd - Proprietor

SUMMARY:

Extensive knowledge of precision optical components and assemblies, practicing master optician.

EXPERIENCE:

May 1994 to present: Crystal River Optics, Livermore, CA

1979 to 1994: Humphrey Instruments and Carl Zeiss Meditec, Inc.

Project Engineer (4/89 to 5/94)

Engineer in charge of optical components, assemblies, purchasing and quality assurance. Wrote procedures for inspection of optical components and assemblies. Reviewed and approved all optical component and assembly drawings. Participated in the development and subsequent production of two new optical instrument lines with responsibility for manufacturing start up and all optical issues. Sustaining engineer for three instrument production lines. Designed and implemented “test eye” for use on ophthalmic refractors that is traceable to NIST and is now an ISO standard. Instituted ESD policy, training and equipment.

Manufacturing Engineer(5/82 to 4/89)

Engineer in charge of optical fabrication, purchasing, assembly and quality assurance. Responsible for sustaining engineering for two instrument production lines. Designed light meter to calibrate and test optical instruments in the field saving $270K over the planned purchase of Minolta meters. Designed tooling and wrote procedures for complex optical assemblies.

Optics Manager(4/79 to 5/82)

Hired because the company was having serious problems with optics. Solved problems by changing the vendor base, purchasing new equipment, training employees and instituting new procedures. Managed group of 20 employees.

1976 to 1979: Martin Marietta Corp. Orlando, FL

General Foreman. Set up a new optical fabrication, thin film coating and assembly group when company decided to get into military reconnaissance business. Purchase capital equipment, designed plant lay out, hired employees, designed tooling and supervised production. Introduced company to diamond turning technology.

1966 to 1976: Laser Optics Inc.. Danbury, CT

Responsible for production of optical components, coatings and assemblies. Duties included quotations, purchasing, testing, tooling design and quality control. Manager of 19 employees. Hands on fabrication of germanium, silicon, zinc selenide, quartz wave plates and crystals.

1960 to 1966: Perkin-Elmer Corp.. Norwalk, CT

Learned the trade of optical fabrication in the old European tradition beginning as an apprentice and graduating to master optician. Made component for U2 spy plane and satellite cameras.

EDUCATION:

Bachelor of Science in Business Administration.